onveyor onsulting ervices

C

C

S

Spec”WALL”

Introduces their unique vulcanizing system to vulcanize Sidewall and Cleats to the base belt,

tried and tested in over 250 installations with 100% success rate.

The Chemical reaction between the components and base belt initiated by the solvent in the

adhesive formula CHEM”WELD” welds the components together.

The Sidewall and Cleats become an integral part of the base belt, guaranteed to never come

off prematurely.

SPEC”WALL” sidewall belts are made from High quality Abrasive resistant Rubber for long

lasting service.

Every batch of the rubber compound is

tested in the Laboratory for repeat

quality assurance for maximum

flexibility and tensile strength.

Our Standards

SPEC”WALL” sidewall belts are running in production plants throughout the world.

Manufacturing program :

Cross Stabilised Conveyor belting: We manufacture conveyor belts in accordance with the

installation requirements and customers specification. Width :- 350mm to 1200mm Max.

Tensile Strength:

-Plied belts 250 to 1500Kn/m Steel Cord 1600 to 4000Kn/m

Our Story

Conveyor Consulting Services is a community based business establised in 1992 by the

entrepreneurs

David & Rina in association with Jacques together they have more than 99

years of combined experience in the conveyor belting industry.

We have been producing quality Sidewall belting for more than 26 years.

We aspire to keep growing on an international scale as we continue to revolutionise the

Sidewall belting industry.

We offer global delivery and proudly supply:

India, Australia, Chile & Argentina.

WE ARE HERE

E-Mail:

Tel:

+27 11 433 9217

C Cleats

TC Cleats

T Cleats

Cross

stabilised

Base Belt

Wear Belts

Spec”Wall”

Magnet

Belting

Lagging

pads

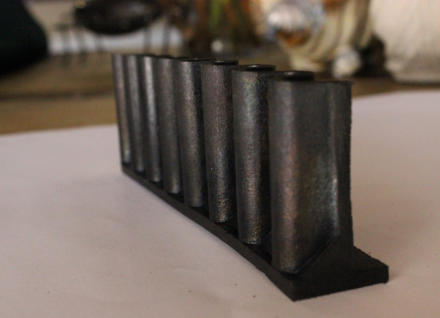

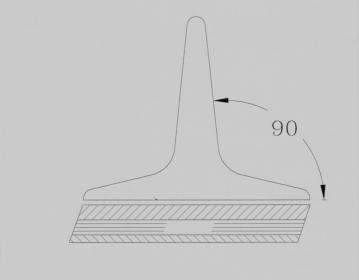

T Cleats

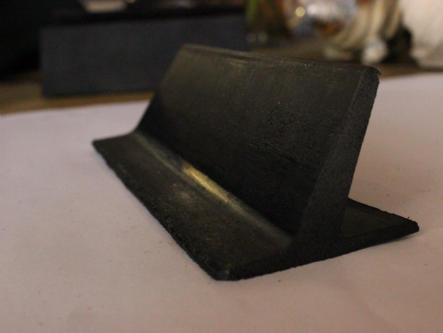

A rubber cleat that stands at a 90

Degree

angle to

the carrier

belt.

T Cleats are

typically

used steep

incline conveyor belts with a maximum

incline angle of 30-35 degrees.

T Cleats are also used as wipers on

overband magnetic belts to clear tramp

iron that the magnet has collected from

the main coneyor belt.

The list below contains

the available sizes and

compatible Spec”Wall”

size.

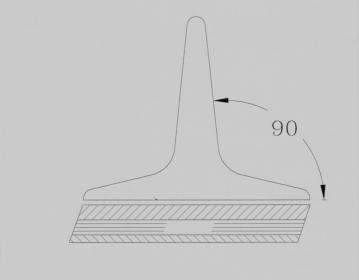

T Cleats

A rubber cleat that stands at a 90

Degree

angle to

the carrier

belt.

T Cleats are

typically

used steep

incline conveyor belts with a maximum

incline angle of 30-35 degrees.

T Cleats are also used as wipers on

overband magnetic belts to clear tramp

iron that the magnet has collected from

the main coneyor belt.

The list below contains

the available sizes and

compatible Spec”Wall”

size.

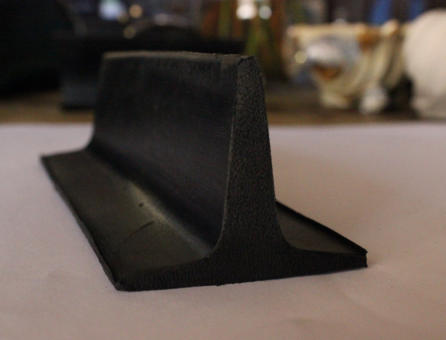

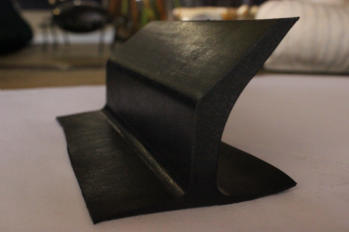

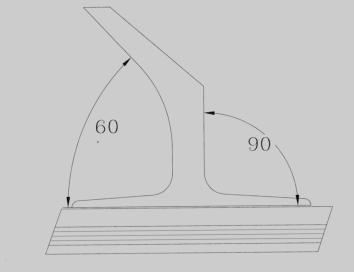

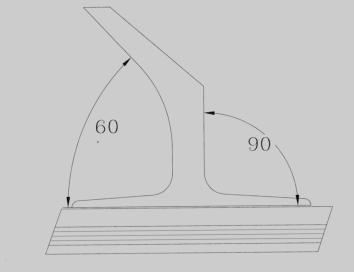

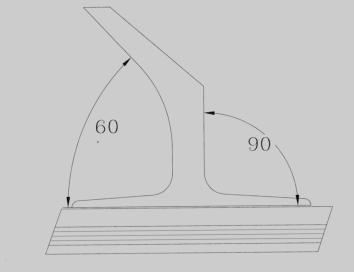

TC Cleats

A rubber Cleat that for the first part is

90 Degrees to

the carrier belt

and inclines at

60 Degrees.

TC Cleats are typically used for

steep angle conveyor belts with

angles ranging from 45-90

Degrees.

For angles 45-55 Degrees belt

speed could become a factor.

The list below contains

the available sizes and

compatible Spec”Wall”

size.

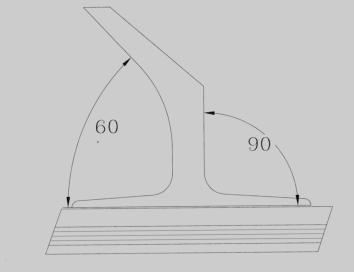

TC Cleats

A rubber Cleat that for the first part is

90 Degrees to

the carrier belt

and inclines at

60 Degrees.

TC Cleats are typically used for

steep angle conveyor belts with

angles ranging from 45-90

Degrees.

For angles 45-55 Degrees belt

speed could become a factor.

The list below contains

the available sizes and

compatible Spec”Wall”

size.

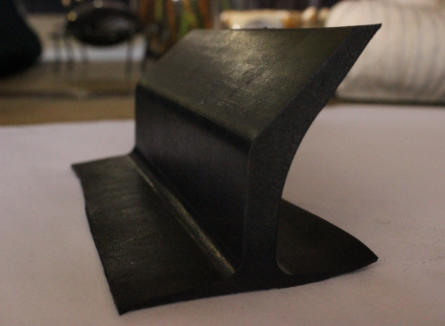

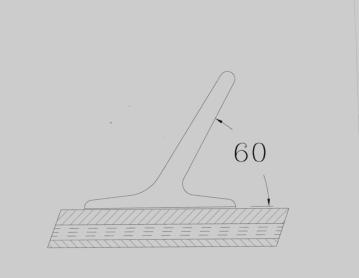

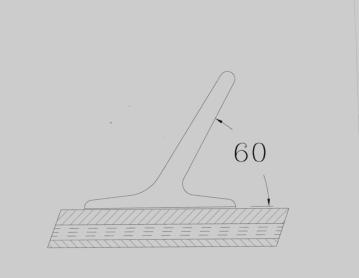

C Cleats

A rubber cleat that stands at a 60

Degree angle

to the

carrier belt.

C Cleats are typically used on

steep angle conveyor belts with

a maximum incline angle of 60-

65 Degrees.

The list below contains

the available sizes and

compatible Spec”Wall”

size.

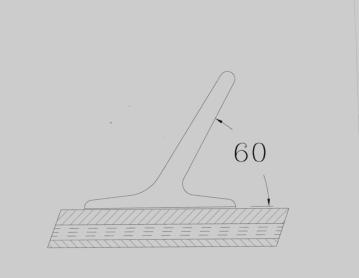

C Cleats

A rubber cleat that stands at a 60

Degree angle

to the

carrier belt.

C Cleats are typically used on

steep angle conveyor belts with

a maximum incline angle of 60-

65 Degrees.

The list below contains

the available sizes and

compatible Spec”Wall”

size.

Wear belts are manufactured from

Polyester Fabric for low stretch and

good wear characteristics.

Wear belts are made to suit customer

requirements: Number of plies,

thickness and Rubber quality make up

the belt requirements.

Thickness:- 5mm to 20mm Width from:

25mm to 1200mm Tol. +-0.5mm

Specified by the client.

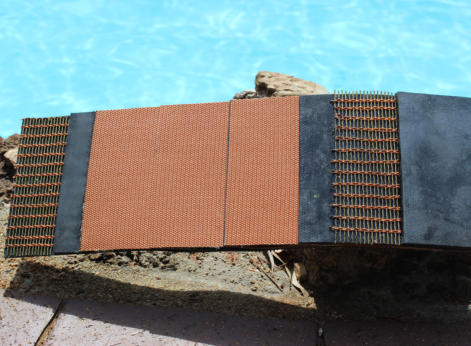

The purpose of an Overband

Magnet Belt is to clean Tramp

iron away from a magnet which is

suspended over the main conveyor

belt.

Typically the magnet belt must

run at the same speed or

faster than the main belt this

results in a very short rotation

cycle. This requires a good

quality top cover, therefore we

reinforce our top cover

extending the life by 5 times

the conventional magnet belt.

Unwanted tramp iron which can

damage equipment further

downstream in the processig plant.

Magnet separators are also used in

scrap yards to remove Ferrous metal

from Non-ferrous.

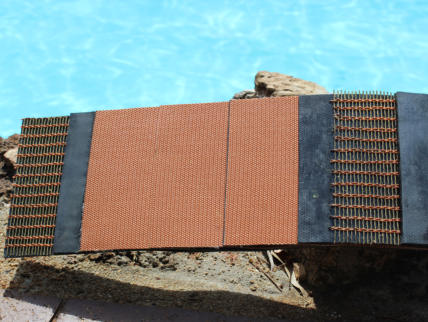

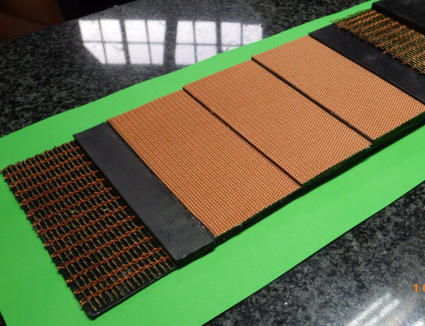

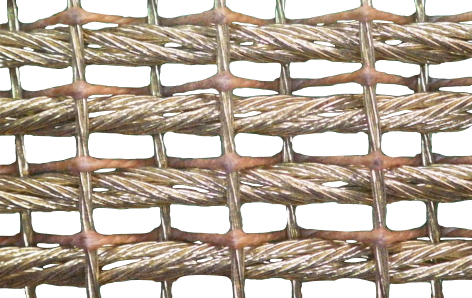

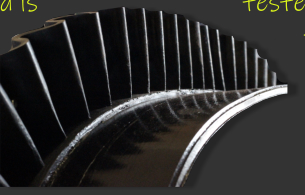

Base

belts are

made

from

pristine

quality

natural

rubber

tested in

the laboratory for consistent repetitive

quality you can rely on, that we

guarantee.

Typical Cross stabilized belt construction.

(Steel cord for illustration purpose)

Plied belts are rated at 250-

1500 KN/m and are available

in widths from 350MM to

1200MM (max)

We offer steel cord reiforcing

for heavy duty applications

rated at 1600-4000 kN/m.

Light Applications:

30mm base Spec”Wall” is generally used for

light duty / less abusive conveyor

systems, available from 40-60mm high.

Medium Applications:

75mm base is the Gladiator of our

Spec”Wall” range able to withstand

incredible workloads, it’s is reinforced with

high tensile fabric for extremely abusive

conveyor systems. Available in 160-280mm

high.

Heavy Applications:

50mm base Spec”Wall” is the Jack of all

trades available from 60-120mm high,

used in all medium / high duty conveyor

systems.

Contact our conveyor belting

specialist for any technical

support.

David Webster:

+27 82 490 1837

Pulley

Pulley

Pads

Double

Single

Calc.

Gain

Diameter

Circumference

Retainer Strips

Retainer Strips

Circumference

mm

mm

Plus Tolerance mm

mm

200

629

4

4

-

624

5

250

786

5

5

-

780

5

300

943

6

6

-

936

9

350

1100

7

7

-

1092

8

400

1257

8

7

2

1263

-6

415

1304

8

4

8

1308

-4

450

1414

9

8

2

1419

-5

500

1571

10

9

2

1575

-4

550

1729

11

10

2

1731

-2

600

1886

12

11

2

1887

-1

650

2043

13

12

2

2043

0

700

2200

14

13

2

2199

1

750

2357

15

14

2

2355

2

800

2514

16

15

2

2511

3

850

2671

17

15

4

2682

-11

900

2829

18

16

4

2838

-9

950

2986

19

18

2

2979

7

1000

3143

20

18

4

3150

-7

1050

3300

21

19

4

3306

-6

1200

3771

24

20

4

3774

-4

25

4

1250

3929

25

23

4

3930

-1

1400

4400

28

26

4

4398

2

1450

4557

29

27

4

4554

3

1500

4714

30

28

4

4710

4

1600

5028

32

30

4

5022

6

1800

5657

36

33

6

5661

-4

2000

6286

40

37

6

6285

1

Standard

conveyor

engineering

usually calls

for a crowned

surface on all

drive pulleys.

A crowned pulley is used to

assist conveyor belt

alignment.

Eliminating erratic

lateral belt movement is

important in preventing

damage to the belt

caused by contact with

the structure. Edge-

Crown lagging creates a

barrel-shaped crown that

improves belt alignment.

Example

Pulley Diameter 500mm facewidth 1,500mm

Pad segments required: 10 X facewidth of 1,50m = 15 meters = 15 only one

meter lengths

Double retainer strips required: 9 X facewidth of 1,50m = 3 meters = 3 only 1

meter lengths, singal retainer strips requierd: 2 X facewidth of 1,50m = 3

meters = 3 only 1 meter lengths, but it is always advisable to have double the

amount of singal retainers in case required = 6 only 1 meter lengths.